1st March, 2024

Pioneering Decarbonisation in Construction: A Blueprint for Change

Explore the construction industry's revolutionary shift towards reducing carbon emissions. Learn more about its commitment to innovative strategies.

In a time when caring for our planet has never been more important, the construction sector is finding itself at a turning point where innovation meets responsibility. Decarbonisation isn’t just the latest trend; it’s a major shift, a solid promise to cut down the global carbon emissions this industry is responsible for. This article breaks down what decarbonisation in construction really means, tackling the basics, the hurdles, and the game-changing strategies setting the stage for a greener future in construction.

Embracing the Green Revolution in Construction

The UN Environment Programme’s report from September 2023 put the spotlight on the construction sector, which is responsible for 37% of the total global carbon emissions. With urban areas growing fast, adding the equivalent size of Paris to the map every five days, the intuitive call is to build less. Or, we could lean on introducing sustainable practices and eco-friendly resources to reduce the carbon footprint. The aim is a significant slash in emissions by 2050.

This means thinking in circles – reusing what we can and prioritising timber and biomass over traditional concrete and steel.

Initiated by the heavy reliance on concrete, steel, and aluminium, which together are behind 23% of global emissions, there’s a push for innovation to make these materials cleaner. The report from the UN and Yale suggests a radical overhaul of how we construct, specifically urging a cut in concrete usage by half by 2060 when most of it would be recycled or made with low-carbon methods.

It’s a challenge that calls for electrifying production processes, scaling up new tech, and getting more from recycling methods.

The shift back to using locally sourced, renewable materials like stone and timber is also part of a broader “back-to-the-future” revolution in construction. The scenarios could involve buildings with living biomass on their walls or roofs, contributing to low-carbon cities. While there’s no single solution to decarbonisation in construction, a mix of new materials and changed processes sets the foundation for change.

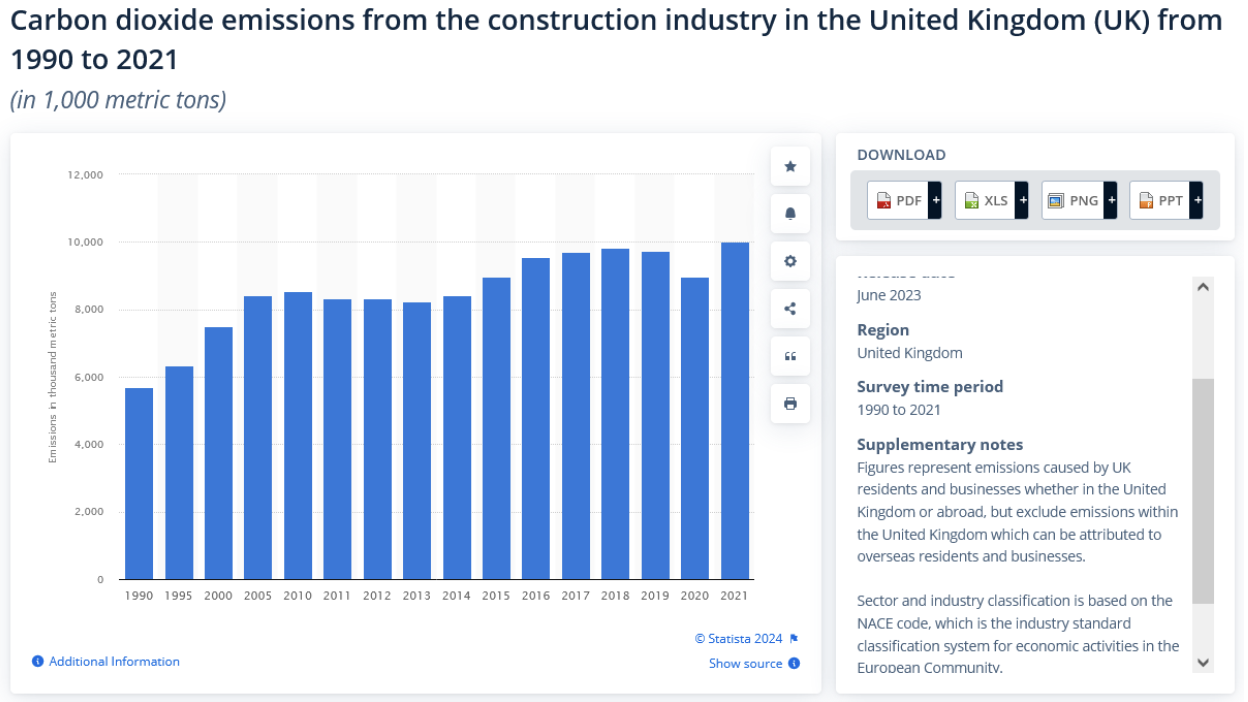

Where the UK Construction Industry Stands on the Global Green Map

According to Statista, the United Kingdom’s construction industry produced over 10 million metric tons of carbon dioxide emissions in 2021. The number marks a whopping 12% rise in just one year, accounting for almost 2.5% of the total UK carbon dioxide emissions in that period. Furthermore, the overall emission was reduced by only 13% between 2018 and 2022, falling seriously short of the 19% reduction goal. Civil engineering contributes to more than one-third of those emissions. Additionally, buildings and their construction activities amounted to 1.7 million metric tons, accounting for 17% of the total emissions from the construction industry.

Transportation has taken the lead as the top source of pollution, edging past the energy supply sector. This shift comes as the move to renewable energy has significantly cut emissions from energy supply, whereas transport emissions have been on an upward trajectory. According to our research, the average piece of hired construction equipment travels 62 miles between its supplier and the construction site. With the average project sourcing 167 pieces of equipment, the total average distance travelled (in round trips) is 20,708 miles per project. This presents a massive source of unnecessary emissions before the equipment arrives on-site. The good news is that it leaves significant room for improvement. Procuring from a localised supply chain network opens opportunities to reduce transportation time and distance. At YardLink, 95% of the products we help source are delivered within 15 miles of each project – 75% closer than the industry average.

It is, therefore, clear why decarbonisation in the construction industry is not just a matter of compliance but a critical step forward. Bearing responsibility for a significant chunk of emissions, the time has come for the entire industry to participate actively in reducing its carbon footprint, aligning with broader environmental goals.

Unpacking the Basics: What is Decarbonisation in Construction?

In summary, decarbonisation in construction implies a set of steps and plans designed to cut down on carbon dioxide emissions throughout a project’s life.

This involves everything from how we choose and buy building materials to managing how things run on the job site. Making smarter choices in supply chain management will ensure the project is as green as possible right from the get-go. The next step is keeping that commitment going by focusing on reducing the emissions further.

The Pillars of Decarbonisation In Construction

Decarbonisation in construction is a movement: a push towards making individual aspects of the industry greener while looking at the entire process holistically.

The global strategy rests on several key pillars, each a cornerstone for a more sustainable future. These are energy efficiency, electrification, renewable energy, and intelligent grid-enabled programs. Translated to a practical approach, that means:

- Rethinking traditional practices

- Adopting innovative technologies that can help reduce emissions

- Choosing materials that are not only sustainable but also sourced locally

- Implementing advanced monitoring systems to optimise the use of machinery and reduce idle times.

The industry can significantly reduce its environmental impact by taking a comprehensive approach covering every construction phase, from the drawing board to the daily grind on-site.

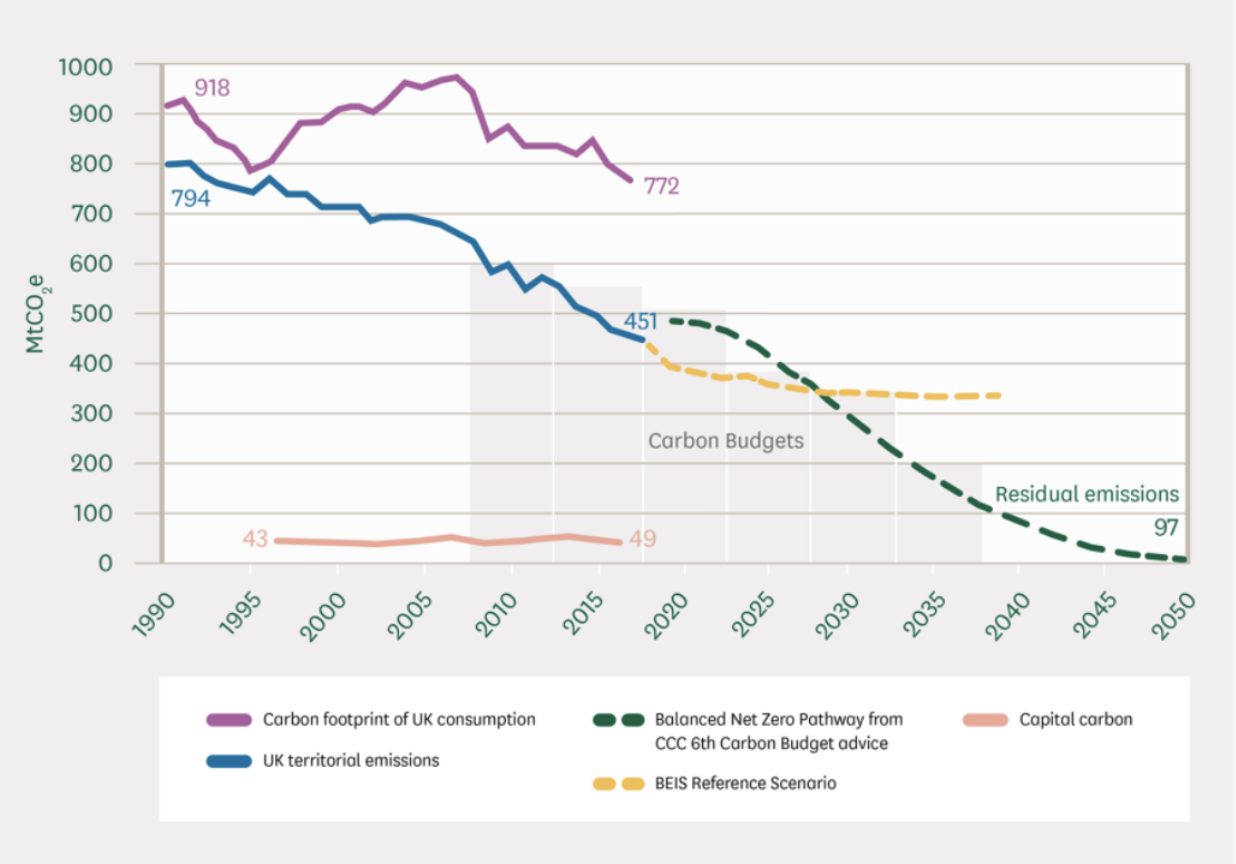

Source: UK Parliament

The Carbon Conundrum: Navigating Global Challenges

The path to decarbonisation, however, is fraught with challenges. Entrenched procurement practices prioritise cost over carbon, while the sector’s fragmented nature often impedes unified action.

The comprehensive Shell and Deloitte report reveals how much the pace of decarbonisation in the construction sector varies across different geographies, influenced by local construction markets, governmental policies, economic conditions, and societal awareness. Europe is recognised as a global leader in this space. Stringent regulations and a high number of construction businesses exemplify its collaborative, proactive approach to achieving the net-zero 2050 goal.

In contrast, while also aiming for a net-zero target by 2050, the United States exhibits a slightly different decarbonisation trajectory in the construction sector. The decentralised nature of its regulatory environment and the variation in state-level progress obstruct the path with a specific set of challenges. However, recent policy developments, such as the Inflation Reduction Act and the Buy Clean California Act, signal a growing momentum.

Meanwhile, China and India, with their net-zero targets set for 2060 and 2070, respectively, are at different stages of their decarbonisation journey. China’s scale, rapid urban development, and significant contribution to global cement and steel production make its pathway crucial to the international effort. At the same time, progress is tempered by current priorities for economic growth and infrastructure development over environmental sustainability. India, facing similar challenges, has a lower regulatory focus and societal pressure on decarbonisation within the construction sector.

How Can the Construction Industry Reduce Carbon Emissions?

Along with the change in building materials, Shell’s report also suggests that the key focus is on adopting modular building techniques. The integration of digital tools like Life Cycle Assessment (LCA) calculators and Building Information Modeling (BIM) can significantly optimise design and reduce waste.

The report highlights successful case studies, including the construction of Singapore’s world’s tallest modular buildings, to illustrate the potential environmental and efficiency gains. It underscores the importance of industry-wide collaboration and the adoption of new models that align financial incentives with sustainability goals.

Revolutionizing Procurement Practices

To overcome the hurdles on the path to decarbonisation in construction, we need to fundamentally change our approach to procurement. In other words, the key is to elevate sustainability to be as important as cost and speed in our decision-making process. It’s about creating a market environment where low-carbon products and services are not just an alternative but the preferred choice.

Empowering the Workforce with Sustainable and Digital Solutions

Equipping the workforce with the proper knowledge and tools is another essential step in driving our sustainability goals. Combining endurable practices and digital technologies can significantly improve our performance, making processes leaner and more efficient. In the long run, this dual focus empowers employees to make informed decisions, setting a new standard for the industry.

Harnessing the Power of Local Sourcing and Real-Time Monitoring

Leveraging digital tools for local sourcing and real-time equipment monitoring emerges as a highly effective strategy. This approach significantly reduces the carbon emissions associated with the construction industry, making it even more sustainable.

Green supply chain management plays a substantial role here. It’s about choosing suppliers with product availability closer to the construction site, which, in turn, lessens the environmental impact of long-haul deliveries. Using digital platforms to source materials and machinery locally reduces transportation distances, dramatically reducing vehicles’ emissions.

Real-time monitoring of construction equipment through digital tools ensures machinery is used efficiently. It helps transition to cleaner energy sources for equipment, like electricity or hydrogen, minimising reliance on fossil fuels. By monitoring equipment usage closely, you can avoid unnecessary idle times, further reducing emissions.

Building a Better Legacy With Green Supply Chain Management

The innovative use of technology can guide the industry towards more sustainable practices, such as using recycled materials or hiring low-emission equipment alternatives, enhancing the overall green footprint of construction projects.

Digital supply chains, like YardLink connect customers with local suppliers, enabling 95% of products we help source to be delivered within 15 miles of each project. Procuring from a localised supply chain, we reduce carbon emissions and curtail overspending on logistics, fostering efficient, green supply chain management.

By championing innovative practices, embracing digital and sustainable solutions, and prioritising local suppliers, we strive to catalyse a seismic shift towards a greener, more sustainable future.

Join us in this journey, for the path to decarbonisation in construction is not traversed alone. It demands collaboration, conviction, and a bold reimagining of what it means to build.

YOU MIGHT ALSO BE INTERESTED IN