18th January, 2022

How Concrete Printing Is Changing the Face of Construction

We explore how concrete printing has changed the face of the construction industry, and the benefits. We also give examples of concrete printing in action.

Technology has forever changed the construction industry, just look at concrete printing for the best example of that.

3D printing, otherwise known as additive manufacturing, has been around since the 1940s, used to craft three-dimensional objects, typically via a robotic arm mounted on a crane.

The materials used in 3D printing do vary, with everything from plastics to liquids being involved within the process. In terms of 3D printing in construction, concrete is one of the main materials used. You can print metal, but it is quite expensive, which is why most opt to print a mould and then use that to craft the component.

3D printing and construction make quite the pair when you consider the outright potential this type of technology has in the grand scheme of things. For example, printing an entire building is entirely possible.

The ability to fabricate intricate shapes, and even buildings from the ground up, make it impossible to ignore from a project management standpoint — or just anyone involved in construction to begin with.

Who knows, maybe in a few years your projects could be designed in a computer and then printed in front of your very eyes. Continue reading to find out more.

What Is Additive Manufacturing?

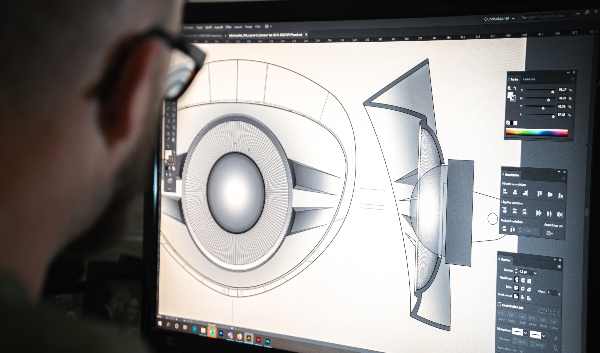

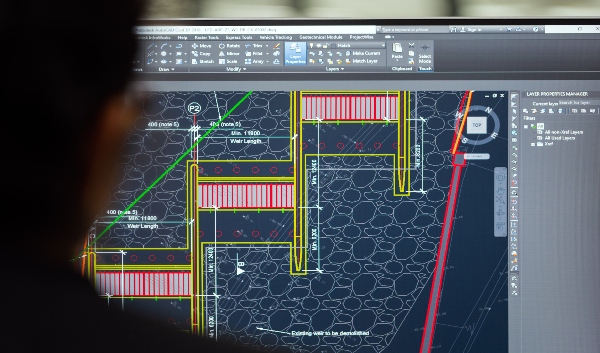

We’ll begin with an all-important question: what is additive manufacturing? Additive manufacturing is where, through computer-aided-design (CAD), a three-dimensional object is created layer upon layer in precise geometric shapes.

The materials used in this process do vary and include components like metal, plastic and concrete — with plastic being what most associate with 3D printing, generally. For context, additive manufacturing — often shortened to ‘AM’ — is another name for 3D printing.

There are seven types of additive manufacturing of note:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- VAT Photopolymerisation

Additive manufacturing has aided multiple industries in the past, due to its ease of use and attention to detail. In aerospace, 3D printing has created parts for aircraft, and in the medical industry, custom surgical implants have been made for patients using this technology.

In the construction industry, additive manufacturing is considered to be the next progressive step, and could one day print skyscrapers amongst other buildings.

How Does 3D Printing In Construction Work?

3D printing in construction is an interesting one, as interesting as all of the other applications mentioned above, in our opinion. After all, the size and scale of construction is on a completely different level. So, how does it work, specifically?

Well, it can either involve the use of a machine fit with a printing arm to build a project from scratch on site, or, one could print all of the parts elsewhere and assemble them piece by piece.

The 3D printers used in construction and concrete printing aren’t the same as those you might have in your office. They tend to be a lot larger and require a CAD or BIM programme to run them.

Once the instructions are inputted, the arm of the printer will then begin injecting materials onto a platform (usually concrete). The nozzle will follow a set path over and over again, adding an additional layer on top until the task is complete.

How long it takes to finish will depend on the intricacy of the design and its size. Although, you’d have to imagine that the speed and effectiveness of this tech would only get better in time, perhaps even building full homes within a 24 hour period or less.

Benefits of Concrete Printing

Crafting a building this way comes with various benefits, as you can imagine. This included a greater degree of accuracy and time taken to lay the concrete in contrast to those doing it by hand.

These are but a few examples, let’s look at some others:

Innovative/Experimental Designs

Physics and practicality often get in the way of certain construction projects and the imagination behind those involved in the designing process. With 3D printing, the rulebook is thrown out of the window, as anything is possible.

It doesn’t matter how complex or how unusual your designs are, additive manufacturing will bring it to life, allowing for some pretty out there shapes, shapes that would be nye on impossible to craft by hand.

We should preface this by saying that not every client will want an experimental touch, but for those that do, 3D printing could unlock a series of never-ending possibilities for architects.

Quicker Builds

AI in construction across the entire construction industry has benefitted how long it would typically take to finish certain projects, and concrete printing is no exception. It’s the best example to give in terms of how far we’ve come technologically speaking, if anything.

Think about it, a 3D printer can work a full day and never grow tired, and can even work on weekends. Also, a 3D printer can lay concrete a lot quicker, and with a greater level of accuracy compared to work completed by a human.

By finishing a project ahead of schedule, you create more space in the diary, allowing you to generate more business as a result.

Reduced Costs

By using a 3D printer, you could save money by not having to spend money on areas you otherwise would as it’s all automated. Saving time and saving money, this should be the primary goal of every project manager.

Sure, the outright cost of buying a 3D printer big enough to handle these tasks could be expensive whenever it’s made available. Still, the printer could pay for itself when you consider how much money has been saved over time.

You also cut down on the amount of waste produced by heading in this direction, which means you won’t need to spend as much money on removing it.

Not As Much Waste

3D printing in construction works within its own means. Meaning, it only uses the material required to print what you’ve asked it to print. This is great for many reasons, the most obvious being: you no don’t produce an excess of waste.

Waste management is a big issue for many construction companies, and finding solutions to these problems can be rather difficult. Perhaps, 3D printing could be the answer.

Drawbacks Of Concrete Printing

If we’re to provide you with a full idea of what concrete printing is and how it works, then we need to look at any potential drawbacks alongside the above benefits. It’s still early days for printing buildings, but some have highlighted some interesting points that highlight limitations of the technology and the resulting structures.

Here are some of the potential drawbacks of concrete printing and 3D printing in construction, generally:

Initial Costs

Investment in 3D printing technology could be incredibly expensive, so expensive that it could be seen as a barrier to entry. Most construction companies operate on thin profit margins, which would make paying for a 3D printer next to impossible.

In time, renting or leasing a construction-optimised 3D printer could be an option. It could be a while before this happens, but it’s something we’d definitely consider at YardLink, as a dedicated provider in construction-based equipment.

Integration Difficulties

Building four walls out of concrete is one thing, it’s another to have a building that takes into account the various components that make up a building (plumbing, electrical, etc). This applies to both types of concrete printing construction.

It’s one thing to create a rather unique-looking building, it’s another to make it inhabitable — or have it feature certain elements. That’s the point some sceptics are looking at and highlighting.

There needs to be synergy between all departments involved in this process to avoid integration difficulties.

Interest In Printed Buildings

If there’s one thing to agree on, it’s that 3D printed structures and buildings are very impressive to sit and marvel at. How many people with this opinion would want to live in one? The answer might surprise you.

This goes back to what we were saying before, how 3D printed homes that go against convention won’t be for everyone. Prefabricated homes are the perfect case study to use here as these are homes that look different from the standard brick and mortar places. However, they aren’t nearly as popular as they should be based on their visual aesthetic.

Examples Of Concrete Printing

There aren’t a lot of concrete printing examples to cover, despite the technology being as impressive as it is. That’s not to say that no one has ever printed a full building before, because a few have, all with varying results.

Many of the concrete printed examples we’re about to provide were done to promote 3D printing in construction and its overall potential. For example, in 2014, a Chinese firm printed 10 full-sized houses in a single day.

Companies from around the world have all had a hand in printing these buildings/structures, and show no signs of slowing down.

3D Printed Bridge By Acciona

The title of world’s first 3D printed bridge belongs to Acciona, a Spanish infrastructure company that developed and printed the ‘3DBRIDGE.’ The title technically belongs to the Institute of Advanced Architecture of Catalonia (IAAC) too, who led the project.

It took around a year and half from concept to completion, with the structure placed in Castilla-La Mancha Park in Alcobendas, Madrid. The 3DBRIDGE is 12 meters in length and 1.75 meters wide.

The design of the bridge is described as ‘parametric’ and is made from micro-reinforced concrete. This 3D printed bridge was unveiled to the public in early 2017, kicking off a trend of additive manufactured bridges appearing in urban areas.

Largest 3D-Printed Building By Apis Cor

From one title holder to the next. In 2019, robotic construction company Apis Cor used its technology to build a two-story office in Dubai, hailed as the world’s largest 3D-printed building to date.

The structure measures 9.5 meters high with a floor area of 640 square meters. Apic Cor actually developed a gypsum-based material used in the makeup of the building. Unlike some of the other 3D printing in construction examples shown, this building was built completely out in the open and on site, rather than piece by piece.

A crane was used to move the machine to and from each position to craft every part of the building. While the foundations of the building are traditional, the columns and walls of the building were printed and reinforced with concrete and rebar.

The Biodegradable Home By WASP

While it’s not an example of concrete printing per say, it’s still worth mentioning if only to highlight what is possible with 3D printing in construction. We’re of course referring to the 3D-printed home made from Italian developer WASP that is made from soil and agricultural waste.

Like the Apis Cor office in Dubai, this home was printed on site, using mud and other materials within the surrounding area. Waste materials from rice production such as chopped straw and rice husks were also used in the printing process.

According to the company, the home will turn back into soil if it isn’t maintained, making it fully biodegradable as advertised.

Office Of The Future By Killa Design

The office of the future by Killa Design is one of the best examples to show people that ask what is additive manufacturing, simply because of how innovative it is. Images of this building look fake, but seeing is believing.

The building used Chinese company WinSun’s tilt-up technology to bring it to life. This is where the floor, walls and ceiling are all printed on their side in 2D layer by layer, before being tilted vertically.

Each part of the building was printed separately at WinSun’s factory in China, before being shipped to the office site in Dubai. This single-story, multi-building campus was designed by Gensler for the United Arab Emirates National Committee as the headquarters for the Dubai Future Foundation (DFF).

In the original press release announcing the opening of the office, it was stated that labour costs were cut by more than 50% by printing the building. Only one individual was needed to monitor the printer, while several others handled the electrical engineering.

How Concrete Printing Is Changing the Face of Construction

The future of construction could be designed, layered and executed by 3D printing technology. We’ve already shown that there are already multiple examples out there of companies using 3D printing in construction.

While it might be a while yet before the technology takes off in other parts of the world, there’s no denying its appeal. It’s something to remember the next time someone asks you what additive manufacturing is.

There’s no telling what is/isn’t possible with concrete printing, which is what makes it such an interesting topic to cover. Try not to forget about the benefits of 3D printing in construction too, those being reduced costs, experimental designs and quicker builds with no loss in quality.

The quality of your work is something we consider essential, and to confirm quality, you need the right tools/equipment. At YardLink we supply a range of machinery to ensure that your projects are completed to the highest quality possible. Speak to a member of our team to find out more!

YOU MIGHT ALSO BE INTERESTED IN